A customer in the telecommunications industry approached us at Electro-Spec to investigate a plating alternative to silver and nickel finishes that would provide improved wear and performance properties while lessening the impact that rising metal prices were having on their plating costs.

Their silver-plated, high-frequency components were exhibiting premature tarnishing and degradation when subjected to harsh environments, so we offered our Tri-M3™ (Tri-Metal, Tri-Alloy, or White Bronze) as an alternative finish. Its excellent corrosion resistance and low porosity, combined with ease of solderability and exceptional leveling capability and throwing power made it an ideal choice for plating RF connectors. We were able to reduce the plating thickness from 200 µ-in. of silver to 80 µ-in. of Tri-M3™ while providing greatly improved resistance to corrosion and wear.

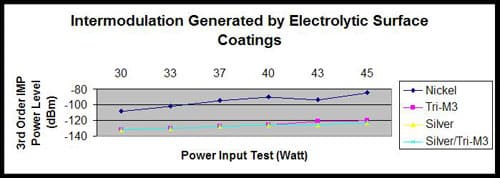

An additional benefit of using Tri-M3™ (Tri-Metal, Tri-Alloy, or White Bronze) was its low intermodulation, or tendency to generate unwanted frequencies during signal transmission. With low surface friction (approximately 70% of silver), high conductivity, and non-magnetic properties, it significantly improved the RF signal and electrical performance of their components. In addition, with the volatility and rising commodity prices of silver and nickel, Tri-M3 enabled the customer to save substantial plating expenses. The price of silver alone has more than quadrupled in the last 15 years, and the reduced thickness requirements of Tri-M3™ made it one-third the cost of what they had been paying for silver plating.

With this tri-metal alloy finish, the customer achieved a winning trifecta of improved wear, improved operational performance, and reduction of plating expense. Contact us today to learn more about the advantages of Tri-M3™.