Ever the innovator, Electro-Spec, Inc.’s engineering team identified a need for a plating process that would enhance the performance of RF connectors. What they developed was the TRI-M3™ (Tri-Alloy, Tri-Metal, or White Bronze) finish; this cutting-edge process represents a dramatic improvement in plating RF and Microwave connectors and components that desire high corrosive resistance and tarnishing behavior.

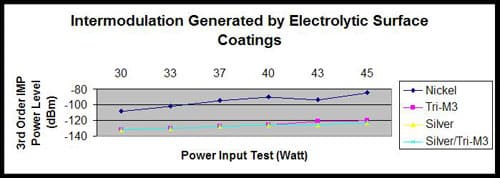

The TRI-M3™ process provides high corrosion and tarnish resistance, with a shelf life that far exceeds traditional silver plating, with superior electrical performance than nickel. This new plating method overcomes the negative characteristics of silver and nickel plating, while enhancing their positive properties. Silver exhibits excellent electrical properties but tends to tarnish and breaks down over time, while nickel provides a longer shelf life and wear characteristics, but exhibits poor intermodulation performance, high permeability, and poor screening effects.

Quickly becoming the finish of choice as a replacement for Nickel, Silver, Tin and Tin/Lead, it possesses the following properties:

- Diamagnetic

- Low Intermodulation

- Excellent Corrosion Resistance

- Low Electrical Resistance

- High Wear Resistance

- Low Porosity

- Exceptional Leveling Capability /

- Throwing Power

- Easily Solderable

- Lead (Pb) Free Deposit

TRI-M3™ coated connectors overcome these drawbacks while providing excellent corrosion resistance (even in harsh environments), and low surface friction that is approximately 70% of silver.

With an average alloy composition of 55% Cu, 30% Sn, and 15% Zn, the deposit resembles a Nickel finish and possesses a hardness similar to Nickel (approx. 600 HV). Due to its favorable coefficient of friction, lubricity, and hardness, Tri-M3TM yields less than 50 mg of material removal per 1,000 revolutions. Additionally, with extremely favorable results in Quick T-change, Salt Spray, Mixed Gas, Heat Damp, and Kesternich tests, the corrosion resistance is virtually identical to Nickel run under the same tests. Finally, Solderability is greatly enhanced with Tri-M3TM, as it can be done with or without a flux, depending upon the age of the deposit. In most cases, an R or RMA type of flux can be used with a Sn/Pb solder on parts that have aged significantly.

Tri-M3TM can also be deposited over Copper or Silver, depending upon the specifications. Particularly used as a plate with Silver, the Tri-M3TM and Silver combination improves the level of intermodulation (until +8 dBM / 180 GHz) and allows stability, better repeatability, and measurement. It can also be used as an underplate with Gold, to replace either Copper or Nickel. Copper, when used in conjunction with Gold, migrates and/or diffuses with the Gold over time. Nickel is a magnetic type of finish and presents an intermodulation issue in Rf connectors at medium and high frequencies. Tri-M3TM as an underplate with Gold, presents both an excellent immersion barrier and diamagnetic finish that is both bright and solderable.

Most importantly, with current environmental concerns in America, Asia, and Europe over the use of both Nickel and/or Lead in components and products, Tri-M3TM presents an alternative finish to either surpass or conform to any regulatory issues.

For more information on this cutting edge plating process, contact Electro-Spec directly.