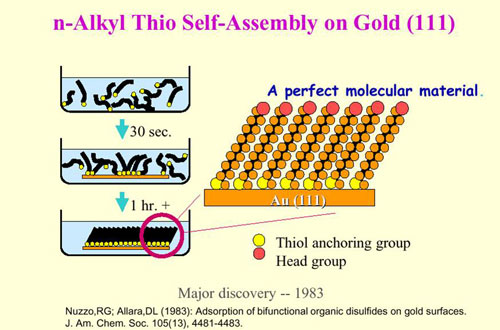

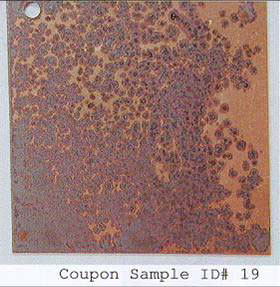

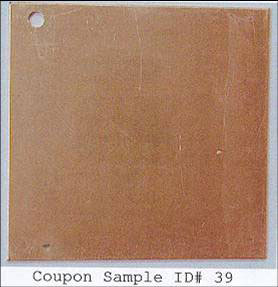

Electro-Spec’s innovative methods for plating include a new technological advancement known as “NanoSHIELD-AU”. NanoSHIELD-AU technology is an advanced plating method that offers enhanced corrosion and contact resistance, with excellent solderability. With a thicker and tighter film build than its predecessor technology (SAM’s), NanoSHIELD-AU delivers a 35% to 75% reduction in precious metal cost while providing equal or superior performance to traditional gold thicknesses.

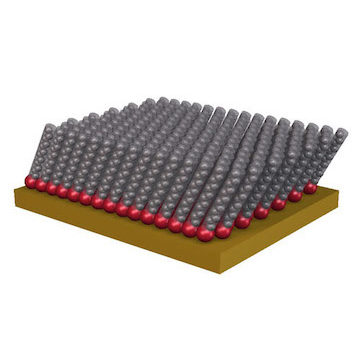

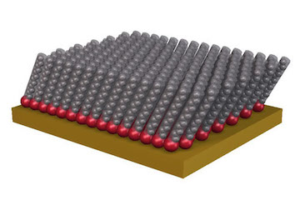

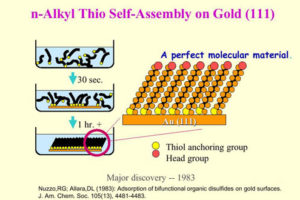

This process employs bi-functional or multi-functional molecules that offer two . . . or more . . . termination groups with different functionality. Typically one end is attached to a specific surface while the other end provides specific functionality. The process consists of a surface treatment (post plate) that forms a protective molecular layer on gold plated surfaces. This process allows for precious metal thickness reduction providing significant cost savings through enhanced corrosion, diffusion, and wear resistance for electronic applications. More importantly, the metallurgical properties of the gold (hardness and purity) are not impacted, allowing conformance to all current industrial, commercial and federal gold plating specifications.