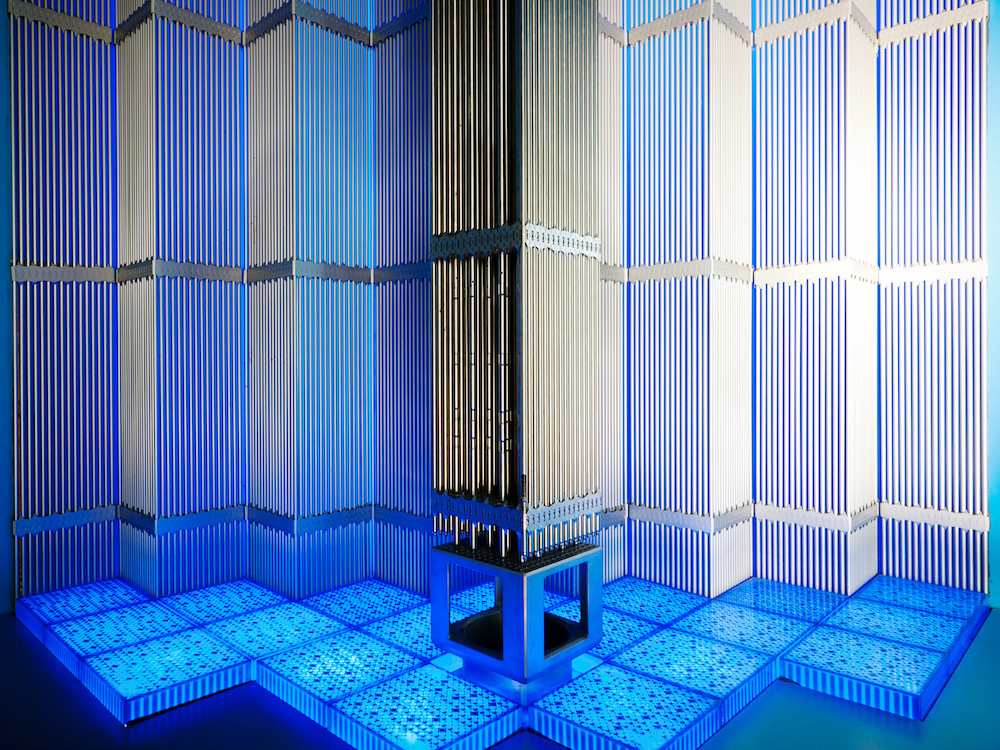

Electro-Spec Carolina worked closely with one of the largest nuclear fuel providers in the world on transitioning their existing plating operation to Electro-Spec’s new facility in South Carolina. This plating operation was utilized to nickel plate the spacer grids that hold nuclear fuel rods in reactors and had been in existence for almost 50 years at the company’s plant. The nickel plating is important in both corrosion resistance of the Inconel grid straps as well as brazing of the straps to form the grid. In an effort to eliminate hazardous materials in their facility, provide cost savings, and to provide security of supply to their customers worldwide, this company sought the help and expertise of Electro-Spec and Electro-Spec Carolina to assist in taking over the plating operations.

Through a dynamic partnership, Electro-Spec Carolina worked extensively with this customer over the course of a year by assisting in the technology transfer of the plating operation, enabled extensive onsite audits performed by their customers throughout the world, and successfully improved the nickel plating process through an automated high-speed plating line. Developing unique fixtures to hold every type of part, Electro-Spec Carolina was able to automate the plating process that had previously been manual, providing cost savings to the company as well as significantly higher throughput. The precision of the nickel plating through this automation effort has led to zero defects in hundreds of thousands of parts since qualification.