Online Tracking And Expediting System

Electro-Spec’s innovative methods for service include the ability to follow each of your orders online. Not only can you track your orders by the minute…you can expedite, change shipping methods, view historical turnaround by part number, download packing lists, download certifications of compliance, and much more. Through our “Customer Portal”, you can access all of your orders as they are received, processed, and shipped back to you. From the time we receive the order until the time you receive the order back, you can track your order through this system.

If an item has shipped, you can click on the “detail link” and it will provide a hyperlink to UPS, FedEx, DHL, or other carriers to complete your tracking information.

If you need additional copies of documentation, you can download a PDF of the document right to your screen for each order.

This system also has the ability to manage inventory (kanban system) for orders you ship to us. You can view finished inventory, raw inventory, in-process inventory, and conduct releases for plating and shipment, right from your desk. You can even upload shipping documents and purchase orders to our system through this portal when doing releases.

This system is updated every 30 seconds on our website and gives you the most up to date information on all of your orders. We understand the urgency of your orders and the need for immediate feedback on the status of these orders. Whether you are in the office or at home or on the road …. you will always have complete access and visibility to your orders through our online tracking and expediting system!

Fully Automated Plating Lines

A key to Electro-Spec’s success has been its automated processing lines. Most automated lines are designed primarily for high volume and have limited flexibility to handle diverse parts. But Electro-Spec integrates TQR software into the plating process to deliver dramatically increased versatility and functionality. This technology easily accommodates a variety of parts, substrates, plates, thickness, and handling methods that present problems for a traditional plater.

Operators can monitor all phases of the plating sequence and make adjustments to times, temperatures, thickness, and more based on feedback they receive through the plating line’s software. Templates and sequences associated to each part and specific to the base material and part geometry, are locked in for historical reference and continuous improvement and efficiencies.

An independent software module called Gravo 10.0 interfaces with the production system and is the first automation software for plating lines that allows real-time access to view and control production operations while, at the same time, collects, analyzes and reports on plant floor activity. Production lines can process 60,000-80,000 jobs per year with 8 transporters and 180 processing positions. Capable of running barrels, racks, wires, and vibratories, the PLC controls all aspects of the operation to ensure precise placement and throughput of each job from the time the order is loaded until it is unloaded off the line.

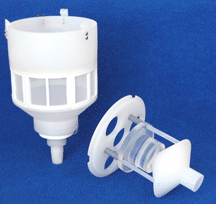

Electro-Spec also has SBE (Spouted Bed Electrode) plating capabilities for micro-miniature and fragile part plating. Rather than a traditional barrel or vibratory, SBE plating is conducted in a stationary chamber with plating solution and rinse water continuously pumped into the chamber and ultrasonics to help move the parts over a cathode ring. Electro-Spec has manual and fully automated SBE plating lines to provide a variety of plating requirements.

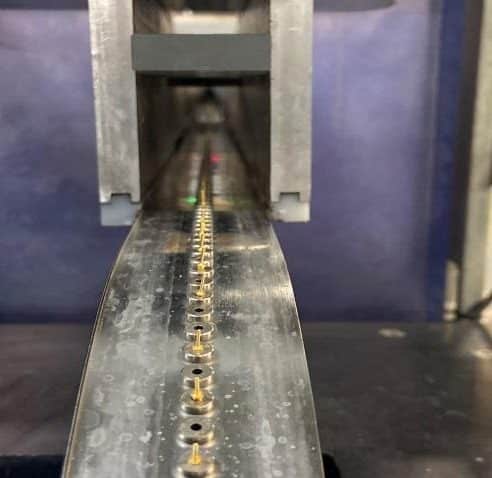

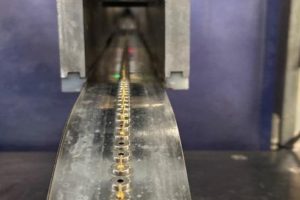

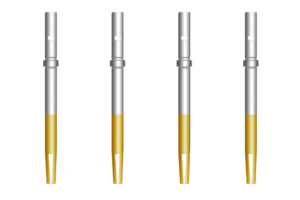

Automated Selective Gold plating lines that utilize controlled-depth plating in a continuous cell allow Electro-Spec to save customers up to 70% of material costs associated to the price of gold by only plating the functional area of the contact or pin. Precision filled and controlled plating cells continuously monitor the level of solution exposed to the parts as they travel through the bath to ensure precise areas of plating (up to .020”) repeatability. Parts travel on a stainless steel belt and are fixtured such that only the area exposed beneath the belt ends up being plated with gold. Once processed, the parts are rinsed and dried and fall off the belt as it winds around a wheel for the return back to the loading station.

Electro-Spec has some of the most unique automated rack plating lines in the plating industry. Initially designed as reel-to-reel plating lines, Electro-Spec has re-engineered the lines to facilitate “loose piece” plating via hooks or racks in a high speed continuously rotating plating line. With open cells on each side, parts are fixtured on hooks or racks and continuously travel through a position on the line. Pumps from the plating baths below the cell continuously pump fresh solutions into the cells to ensure coverage over the parts as they move through the cell and line. Parts are loaded in one section of the line, cleaned . . . activated . . . plated . . . rinsed and finally dried and are unloaded in one rotation of the line. Depending upon the size and geometry of the part, these lines are capable of plating up to 800 parts per hour in one rotation.

Vacuum Vapor Degreasing And Vaccum Ultrasonic Cleaning

Vacuum vapor degreasing eliminates air within the machinery during the process, allowing for higher efficiency, better results, and lowered emissions.

- Pollution Prevention: the combination of a non-flammable, non-corrosive, and non-hazardous solvent with an airless vacuum system significantly reduces the potential for air pollution that has plagued the cleaning industry for decades.

- Cleaner Parts: Throughout the cleaning process, the air that is dissolved within the solvent is eliminated under vacuum, which results in increased ultrasonic power and cleaner parts.

- Low Energy Consumption: There is virtually no energy loss with the unique methods used in airless systems, reducing utility costs and resulting in long-term savings for your company.

- Solvent Recycling: Through a distillation process and solvent recovery system, the solvent can be reused over the course of hundreds of thousands of parts, minimizing the need for continued waste treatment.

Closed-Loop Waste Treatment System

Ovivo technology can separate out 6 different types of metals in the waste stream. Rinses integrated into the plating line are constantly filtered and replenished through the waste treatment system.

Remarkably, cleaning and distillation recover over 99.9 percent of all materials. Even the material removed from the water is dried, pressed, and re-purposed. Silver and gold reclamation from rinses, strips, and plating baths ensures recovery of all precious metals.

Three key attributes of this system that makes it unique in the plating industry:

- DI System – PLC controlled system allowing Electro-Spec to control the conductivity of our deionized water to less than 5 micro siemens (µS). DI System utilizes UV disinfection to allow water to be free of algae and bacteria at all times. The system uses a self-regeneration technology to ensure water is never higher than the programmed set point.

- Nickel Recovery – PLC controlled system allowing proper removal of all nickel-bearing water from rinse processes. This allows Electro-Spec’s water purification system or ION-exchange to work more efficient to recycle or purify the rinse water to less than 30 micro siemens (µS).

- UV Light Disinfection to continuously “sanitize” the water from harmful contaminants.

Finally, 80% of all water used at Electro-Spec for rinsing parts is recycled or purified using an OVIVO ION-Exchange system that will reclaim rinse water at 100 gpm. This system not only removes metal from the rinse water, it also removes any residual cyanide from rinse water as well. This is a PLC controlled system allowing recycled water to always remain below the programmed set point.

Metallurgical & Chemical Capabilities

Understanding its role in the supply chain, Electro-Spec’s commitment to quality can be seen throughout the facility in its Inspection Departments, Metallurgical Laboratory, Chemical Laboratory and its software systems.

Critical process control is achieved through custom software that provides plating and inspection criteria to all personnel throughout the facility. Control plans, Process Flow Diagrams, Failure Mode and Effects Analysis and other industry recognized documentation is maintained through these systems and provides traceability on a part-by-part basis for all customers. Statistical Process Control is integrated into Electro-Spec’s software for the Chemical Laboratory and Inspection Departments. Electro-Spec has developed its own ERP system that encompasses:

- HR/Training

- Production

- Sales/Quoting/Invoicing

- Quality Control

- Purchasing

- Calibration

- Preventative Maintenance

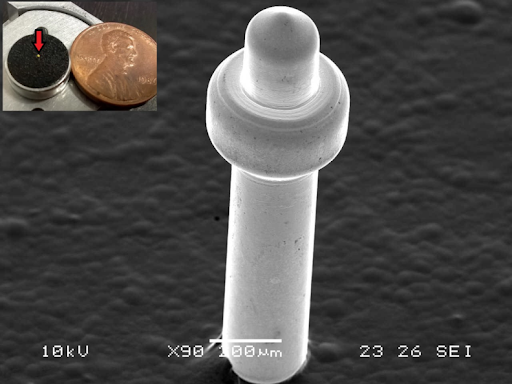

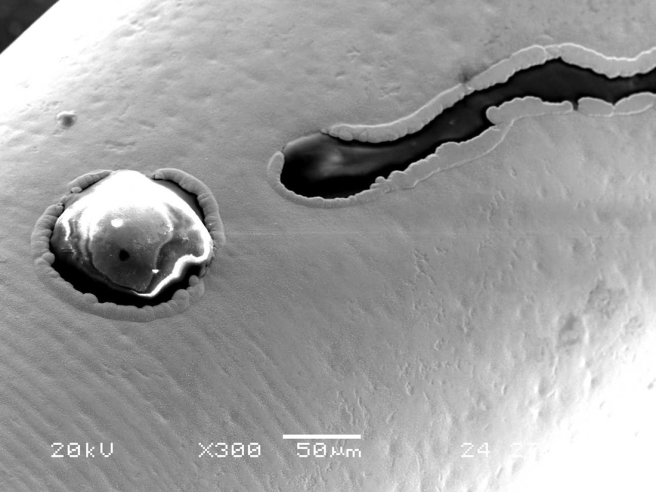

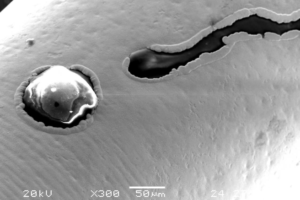

Utilizing only the most advanced equipment like Fluorescence X-Ray Spectrometers, Inductively Coupled Plasma Optical Emission Spectrometry, Scanning Electron Microscopy (SEM), Energy Dispersive X-Ray Spectroscopy(EDS) and various types of other analytical equipment provides Electro-Spec with unparalleled capabilities in process control, failure analysis and product conformance.

Electro-Spec’s Inspection Department can perform virtually any required test to meet most customer and industry specifications like adhesion, thickness, solderability, steam age, quench, nitric vapor porosity, ammonium sulfide and post plate tolerance allowances. Electro-Spec also can measure hardness and provide micro-sectioning to confirm thicknesses of deposits.

These capabilities help Electro-Spec to be certified by Lockheed Martin Space, Raytheon, L3 Harris, Northrop Grumman, Honeywell, Medtronic, Westinghouse Nuclear and many others as an approved plating supplier as well as being certified to ISO 9001, AS 9100, ISO 13485, NADCAP and ISO 14001.